DOE researchers investigate economic and environmental impacts of converting wet waste to renewable diesel

Green Car Congress

JANUARY 3, 2022

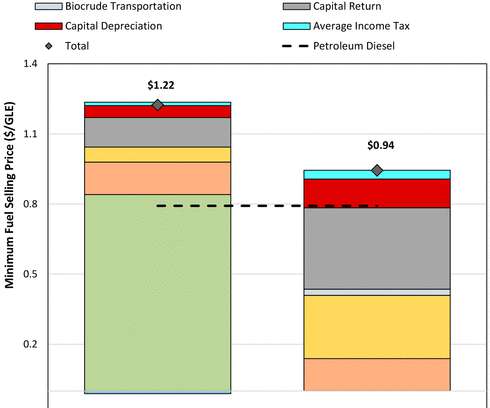

Meanwhile, wet waste feedstocks, such as animal manure and fats, oils, and greases (FOG), represent another important category of resources that could be utilized to produce MCCI bioblendstocks due to its abundant availability. An open-access paper on their results is published in the journal ACS Sustainable Chemistry & Engineering.

Let's personalize your content