New self-purifying electrolyte for high-energy Li-ion batteries

Green Car Congress

MAY 15, 2022

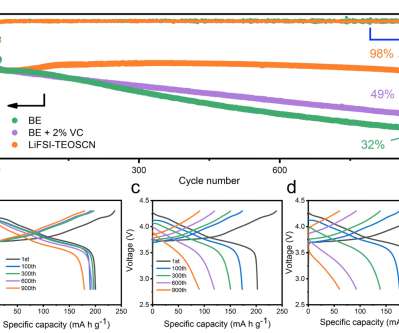

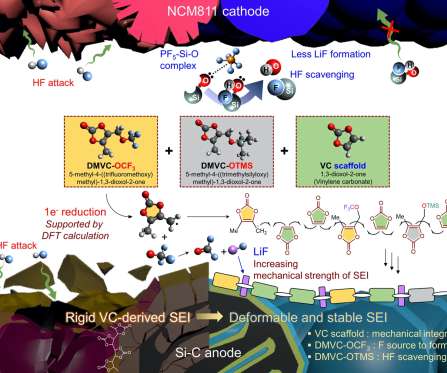

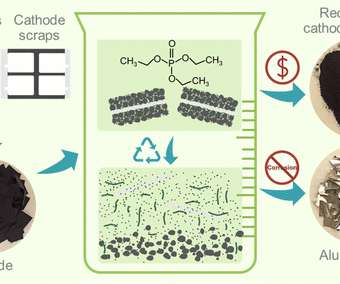

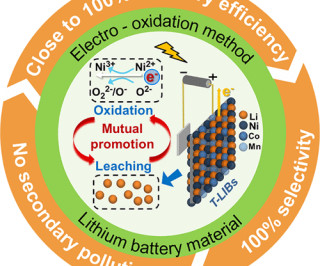

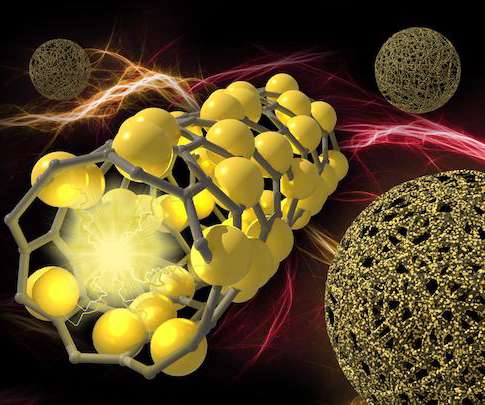

A research team in China has developed a new type of electrolyte for high-energy Li-ion batteries with a self-purifying feature that opens a promising approach for electrolyte engineering for next-generation high-energy Li-ion batteries. Electrochemical performance of Li||NMC811 half-cells using different electrolytes. (a)

Let's personalize your content