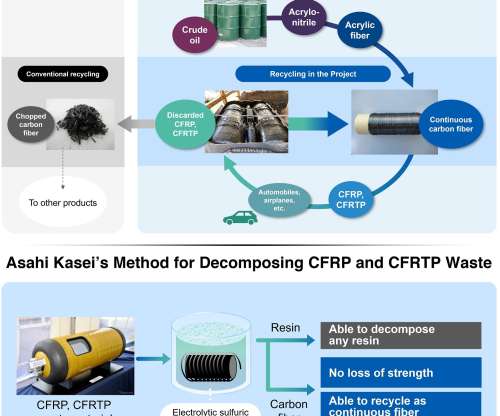

Asahi Kasei collaborates on development of recycling technology for carbon fiber from autos

Green Car Congress

JANUARY 23, 2023

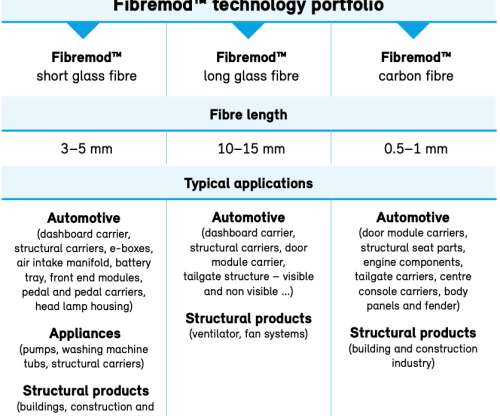

Asahi Kasei, a diversified Japanese multinational company, has developed a new technology for recycling carbon fiber plastic compounds together with the National Institute of Technology, Kitakyushu College and Tokyo University of Science. Thus, these carbon fiber compounds present in vehicles for weight reduction.

Let's personalize your content