PNNL team develops new low-cost method to convert captured CO2 to methane

Green Car Congress

SEPTEMBER 3, 2021

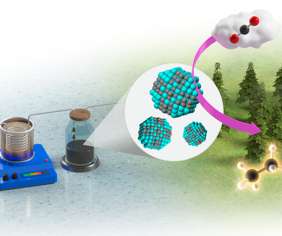

By using a water-lean post-combustion capture solvent, (N-(2-ethoxyethyl)-3-morpholinopropan-1-amine) (2-EEMPA), they achieved a greater than 90% conversion of captured CO 2 to hydrocarbons—mostly methane—in the presence of a heterogenous Ru catalyst under relatively mild reaction conditions (170 °C and 2 pressure). Heldebrant, D.,

Let's personalize your content