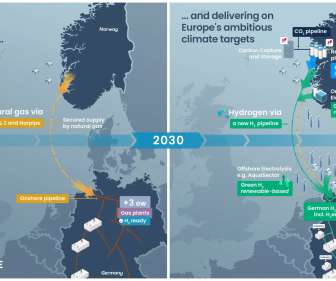

Equinor and RWE to develop hydrogen-fired power plants in Germany, Norway-to-Germany hydrogen pipeline

Green Car Congress

JANUARY 6, 2023

The partners aim to replace coal-fired power plants with hydrogen-ready gas-fired power plants in Germany, and to build production of low carbon and renewable hydrogen in Norway that will be exported through pipeline to Germany. Blue hydrogen in large quantities can make a start, with subsequent conversion into green hydrogen supply.

Let's personalize your content