Li-ion battery waste used in biodiesel production from discarded vegetable oil

Green Car Congress

JULY 22, 2020

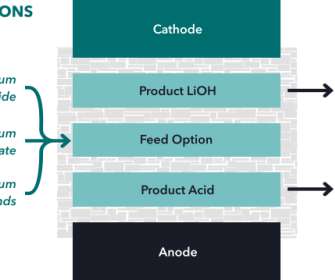

Brazilian researchers have demonstrated a new chemical approach for producing biodiesel from domestic cooking oil waste by using lithium hydroxide mixed with either sodium hydroxides or potassium hydroxides as catalysts. Before, in practice, these were just restricted to sodium hydroxide and potassium hydroxide.

Let's personalize your content