Is It Economical to Convert ICE Car to Electric Car Using Conversion Kit

Get Electric Vehicle

AUGUST 29, 2023

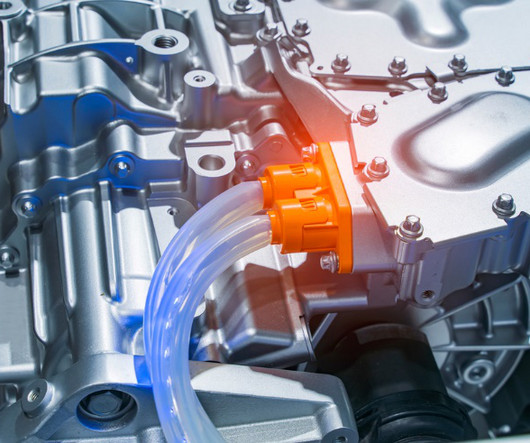

While purchasing a brand-new electric car might not be feasible for everyone due to its higher upfront costs, people are looking for alternatives. converting existing internal combustion engine (ICE) cars into electric vehicles using conversion kits. Cost Considerations #1.

Let's personalize your content