Hatch report finds NOVONIX dry cathode synthesis process offers cost and waste reduction improvements

Green Car Congress

SEPTEMBER 12, 2023

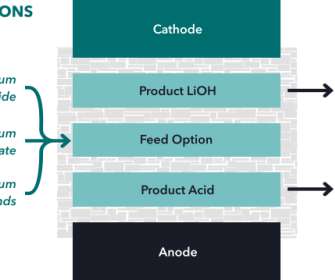

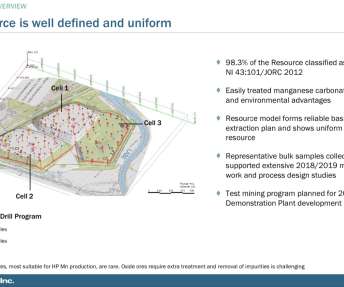

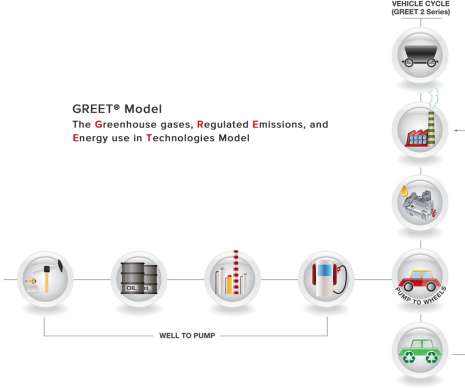

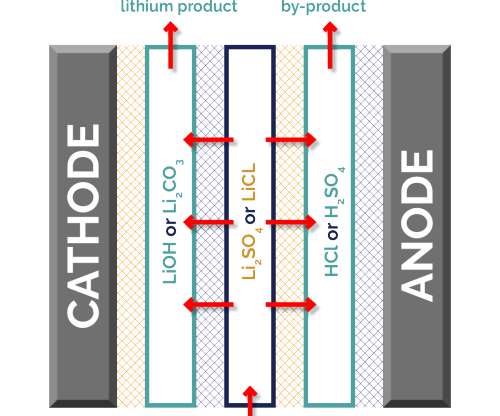

NOVONIX Limited, a battery materials and technology company, announced that Hatch Ltd., a global engineering consultancy firm, has delivered its report that evaluates NOVONIX’s all-dry, zero-waste cathode synthesis process.

Let's personalize your content