BMW Group Plant Landshut light metal foundry recertified by Aluminum Stewardship Initiative (ASI)

Green Car Congress

FEBRUARY 28, 2023

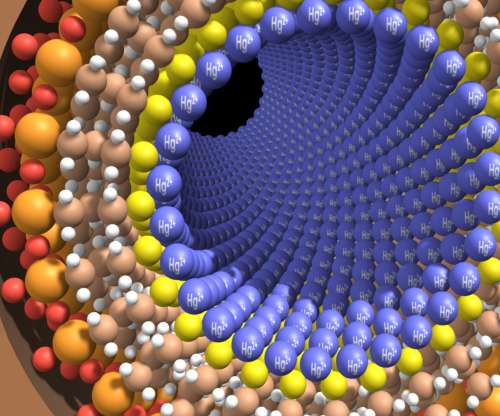

—,Dr Joachim Post, member of the Board of Management of BMW AG responsible for Purchasing and Supplier Network Landshut’s light metal foundry, the BMW Group’s only production facility for light metal casting in Europe, is among the most advanced, most sustainable foundries in the world. Green power is also used to produce it.

Let's personalize your content