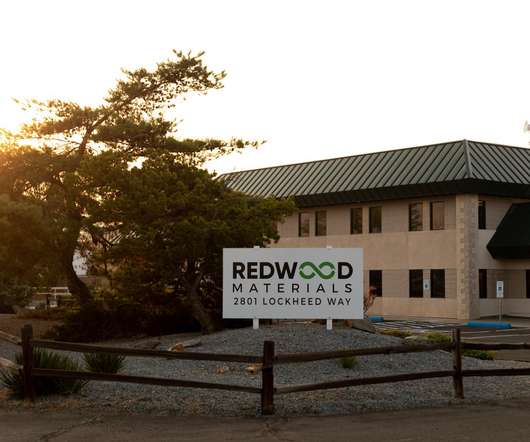

American Battery Technology expands R&D center at the University of Nevada, Reno

Green Car Congress

AUGUST 2, 2022

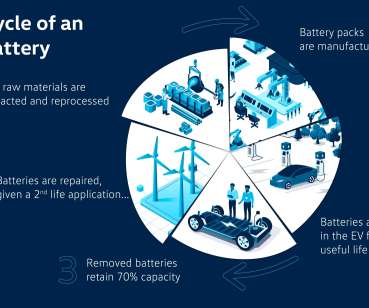

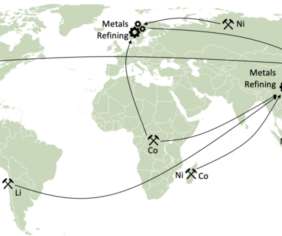

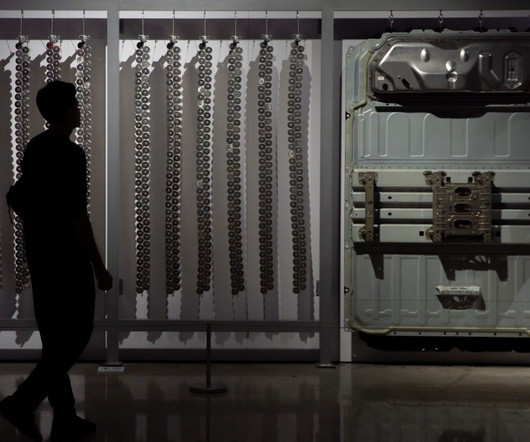

The labs are currently housed at the Nevada Center for Applied Research (NCAR) located at the University of Nevada Reno (UNR). The company’s in-house developed systems have the ability to recover and purify battery metals to the quality standards required to sell them directly back into the domestic battery manufacturing supply chain.

Let's personalize your content