Directly-cooled lighter-weight EV motor made with polymer housing

Green Car Congress

FEBRUARY 2, 2019

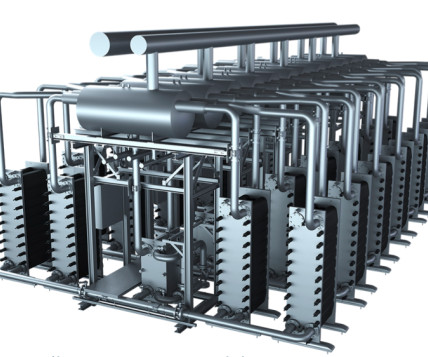

Researchers at the Fraunhofer Institute for Chemical Technology ICT are working together with the Karlsruhe Institute of Technology KIT to develop a new cooling concept that will enable polymers to be used as EV electric motor housing materials, thereby reducing the weight of the motor and thus, the EV itself.

Let's personalize your content