DOE awards $2M to Ohio University to develop products for energy storage and motors from coal waste

Green Car Congress

MARCH 3, 2023

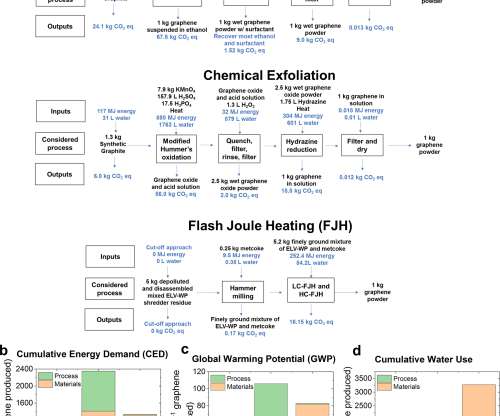

The Department of Energy (DOE) is funding six research and development projects that will repurpose domestic coal resources for high-value graphitic products and carbon-metal composites that can be employed in clean energy technologies. Understanding ultra-conductive carbon metal composite wire for electric motors. Earlier post.)

Let's personalize your content