Researchers use chemical looping process to produce hydrogen from hydrogen sulfide gas

Green Car Congress

SEPTEMBER 13, 2021

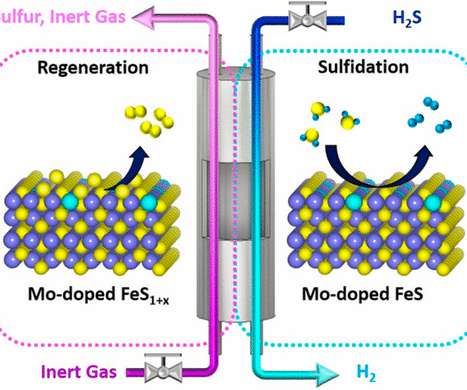

Researchers at The Ohio State University have used a chemical looping process to produce hydrogen from hydrogen sulfide gas—commonly called “sewer gas”. Hydrogen sulfide is emitted from manure piles and sewer pipes and is a key byproduct of industrial activities including refining oil and gas, producing paper and mining.

Let's personalize your content