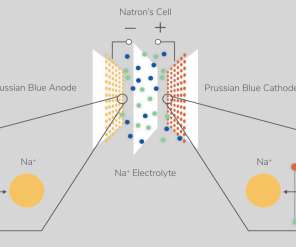

Natron collaborates with Clarios on first mass manufacturing of Sodium-ion batteries

Green Car Congress

MAY 5, 2022

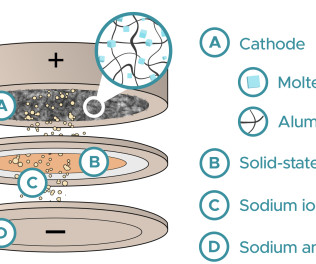

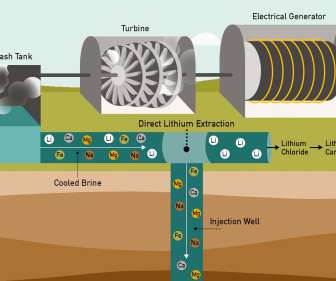

Natron Energy, a manufacturer of sodium-ion batteries, and Clarios International Inc., a manufacturer of low-voltage advanced battery technologies for mobility, will collaborate to manufacture the first mass-produced sodium-ion batteries. Natron has spent 10 years developing sodium-ion battery chemistry for mass manufacturing.

Let's personalize your content