WPI-led team develops dry-print process to make better, cheaper electrodes for Li-ion batteries

Green Car Congress

MAY 22, 2023

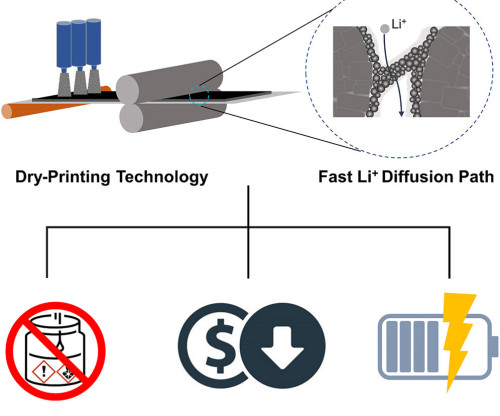

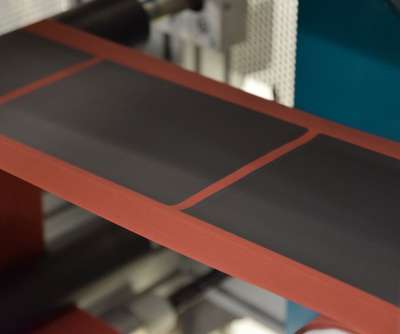

A team led by Worcester Polytechnic Institute (WPI) researcher Yan Wang has developed a solvent-free process to manufacture lithium-ion battery electrodes that are greener, cheaper, and charge faster than electrodes currently on the market. WPI has filed a patent application on the manufacturing technology developed by Wang’s team.

Let's personalize your content