OSU team develops process to clean coal mine drainage and extract rare earth elements

Green Car Congress

JANUARY 4, 2023

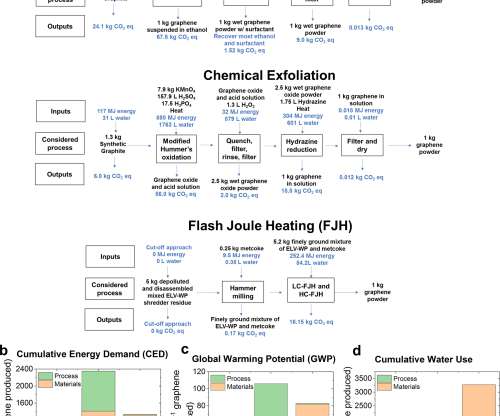

Researchers at The Ohio State University have developed a novel process to clean coal mine drainage and extract rare-earth elements from it. Coal mine drainage (CMD) impairs tens of thousands of kilometers of U.S. CMD, coal mine drainage; TEP, trap-extract-precipitate. —Miranda et al. Miranda et al. —Jeff Bielicki.

Let's personalize your content