SGH2 building largest green hydrogen production facility in California; gasification of waste into H2

Green Car Congress

MAY 21, 2020

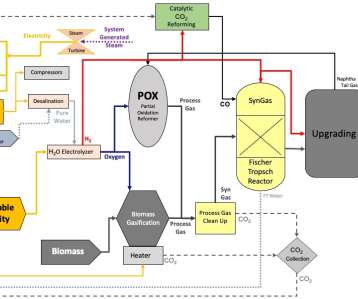

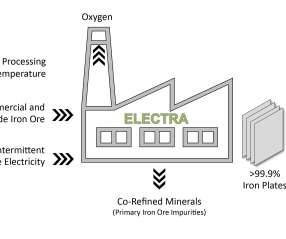

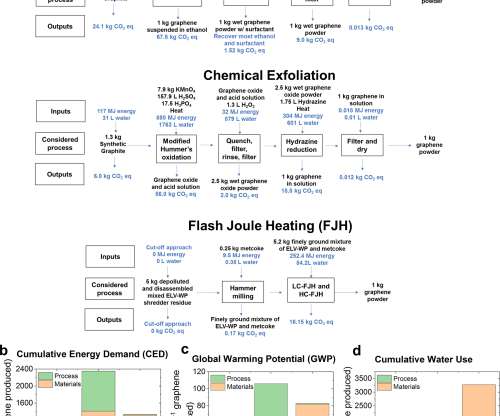

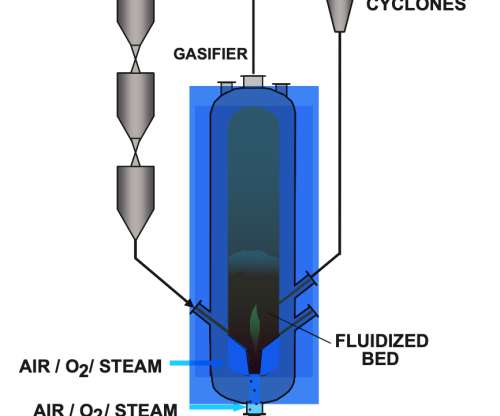

Energy company SGH2 is bringing the world’s biggest green hydrogen production facility to Lancaster, California. SGH2’s gasification process uses a plasma-enhanced thermal catalytic conversion process optimized with oxygen-enriched gas. The facility will process 42,000 tons of recycled waste annually.

Let's personalize your content