KIT studying production of MEAs for heavy-duty fuel cell vehicle systems

Green Car Congress

DECEMBER 23, 2020

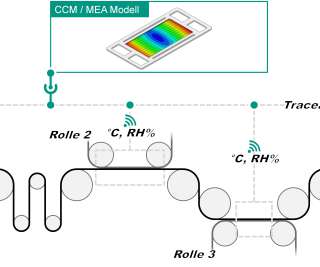

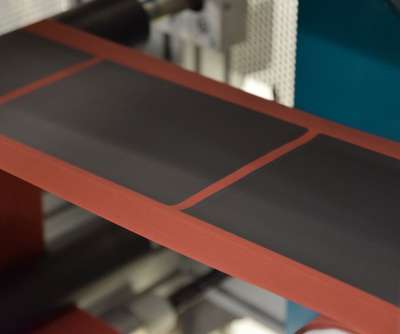

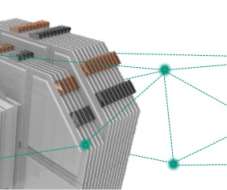

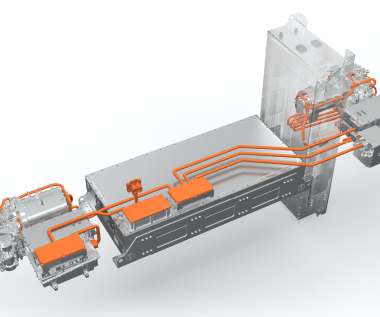

Within the KliMEA project, researchers at Karlsruhe Institute of Technology (KIT) will study drive systems of heavy duty vehicles and fuel cell technology to find ways how future production of fuel cell components can be adapted to these expected new emissions requirements. Schematic representation of roll-to-roll MEA manufacture.

Let's personalize your content