SGH2 building largest green hydrogen production facility in California; gasification of waste into H2

Green Car Congress

MAY 21, 2020

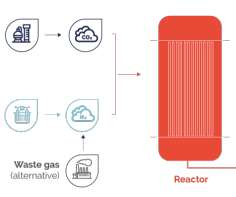

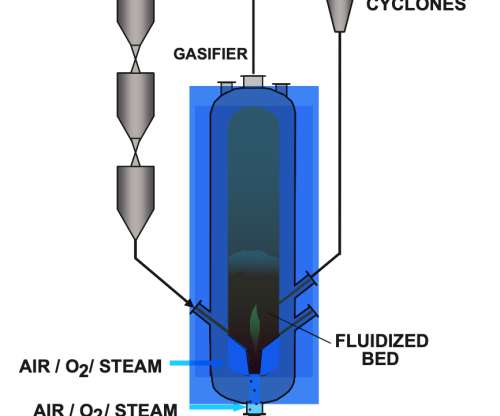

Energy company SGH2 is bringing the world’s biggest green hydrogen production facility to Lancaster, California. In the gasification island’s catalyst-bed chamber, plasma torches generate such high temperatures (3500 ºC - 4000 ºC), that the waste feedstock disintegrates into its molecular compounds, without combustion ash or toxic fly ash.

Let's personalize your content