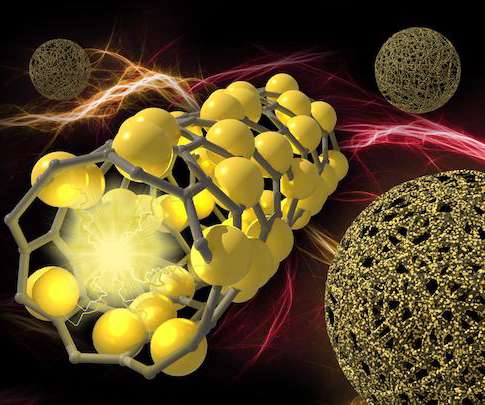

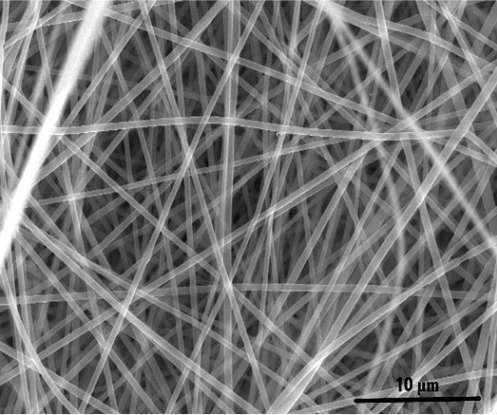

PNNL team develops carbon nanotube-silicon microspheres as high-performance Li-ion anodes

Green Car Congress

MAY 1, 2020

Silicon is an appealing anode material for Li-ion batteries because it can hold about 10 times the electrical charge per gram compared to graphite. Here we design and synthesize hierarchical carbon-nanotube@silicon@carbon microspheres with both high porosity and extraordinary mechanical strength (>200?MPa)

Let's personalize your content