Alfa Laval introduces E-PowerPack ORC waste heat recovery system for ships

Green Car Congress

MARCH 13, 2022

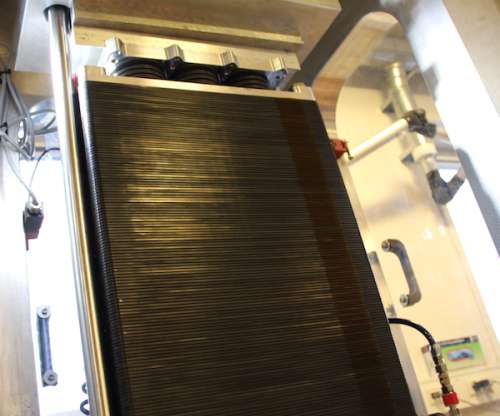

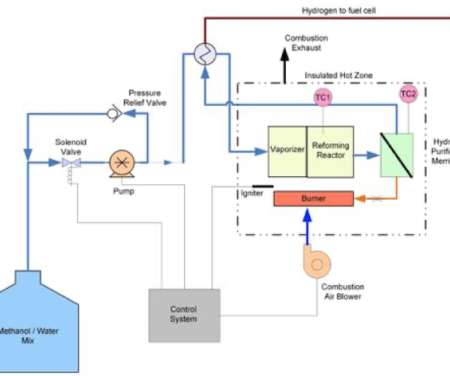

Alfa Laval is introducing the E-PowerPack waste heat recovery system for ships. Able to convert waste heat directly into electrical power, the E-PowerPack uses Organic Rankine Cycle (ORC) technology to reduce ship fuel consumption and CO 2 emissions. —Danny Ingemann, Head of Global Sales responsible for the product.

Let's personalize your content