PNNL team develops new low-cost method to convert captured CO2 to methane

Green Car Congress

SEPTEMBER 3, 2021

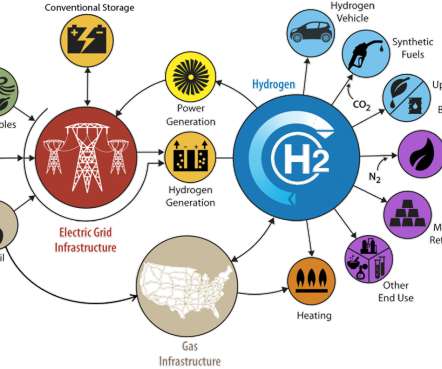

Researchers at the Department of Energy’s Pacific Northwest National Laboratory have developed a new method to convert captured CO 2 into methane, the primary component of natural gas. Conventionally, plant operators can capture CO 2 by using special solvents that douse flue gas before it’s emitted from plant chimneys. Heldebrant, D.,

Let's personalize your content