Rio Tinto achieves battery-grade lithium production at Boron plant

Green Car Congress

APRIL 8, 2021

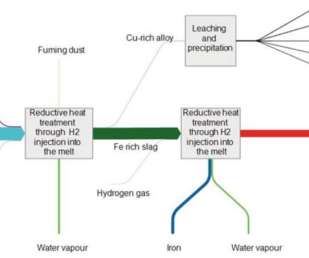

Rio Tinto has commenced production of battery-grade lithium from waste rock at a lithium demonstration plant at the Boron mine site in California. An initial small-scale trial in 2019 successfully proved the process of roasting and leaching waste rock to recover high grades of lithium.

Let's personalize your content