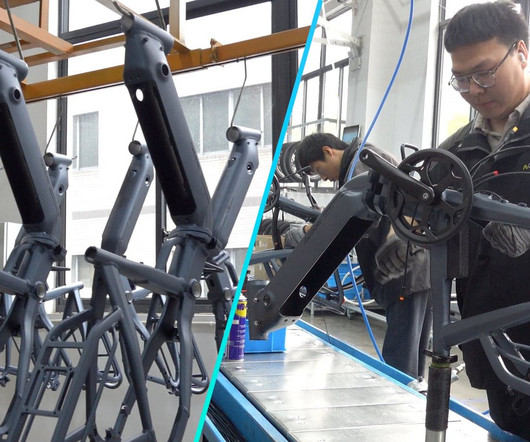

Magna and Ford developing prototype carbon fiber composite subframe; mass reduction of 34%

Green Car Congress

MARCH 14, 2017

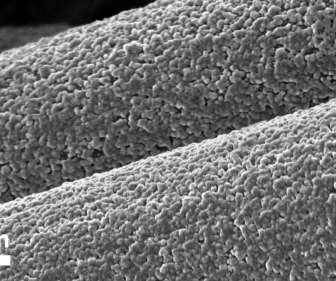

in cooperation with Ford Motor Company, developed a prototype carbon fiber composite subframe which reduces mass by 34% compared to making a stamped steel equivalent. We must continue to work hard to achieve these lightweight solutions at the most affordable costs.

Let's personalize your content