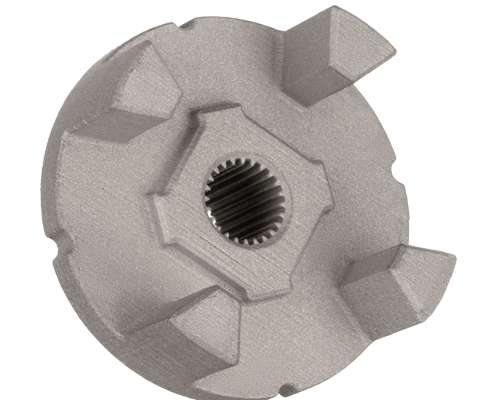

Desktop Metal qualifies 4140 low-alloy steel for high-volume additive manufacturing of end-use parts with the Production System

Green Car Congress

JUNE 8, 2021

Desktop Metal, a provider of mass-production additive-manufacturing (AM) solutions, has qualified the use of 4140 low-alloy steel for the Production System platform, which leverages patent-pending Single Pass Jetting (SPJ) technology designed to achieve the fastest build speeds in the metal additive manufacturing industry.

Let's personalize your content