Yongsoo OWC pilot plant in Korea is being prepared to produce green hydrogen

Green Car Congress

JUNE 7, 2023

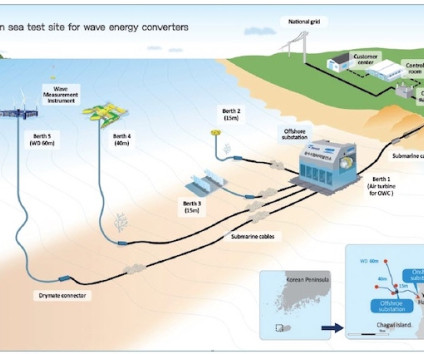

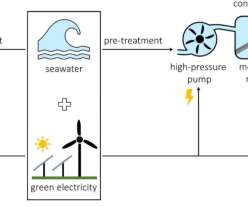

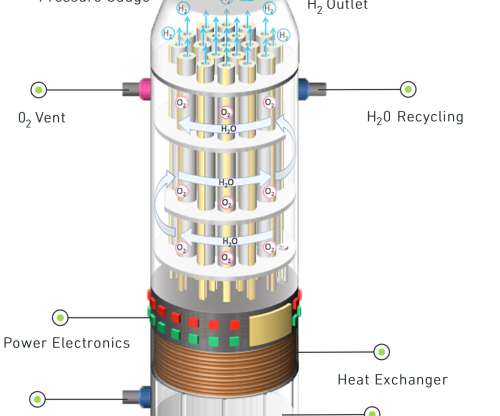

The Yongsoo wave energy power plant, installed at berth 1 in the Korean Institute KRISO -Wave Energy Test Site (WETS), is preparing to produce green hydrogen from next year, according to a report from Ocean Energy Systems. The water depth ranges from 15 meters to 60 meters and is constructed to test different types of devices.

Let's personalize your content