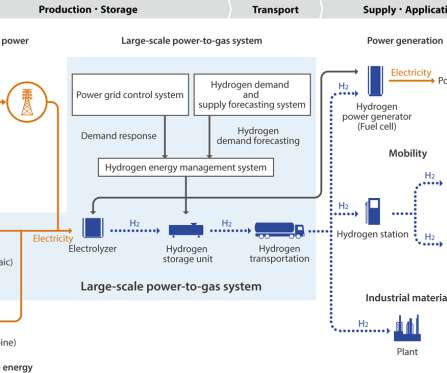

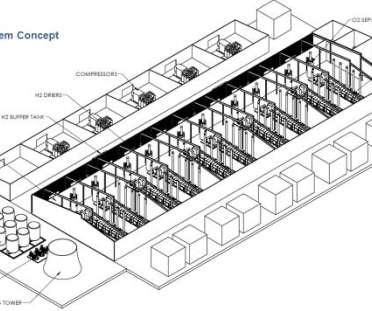

Fukushima Hydrogen Energy Research Field (FH2R) completed in Japan; aiming for low-cost green hydrogen production; P2G

Green Car Congress

MARCH 8, 2020

Japan’s New Energy and Industrial Technology Development Organization (NEDO), Toshiba Energy Systems & Solutions Corporation (Toshiba ESS), Tohoku Electric Power Co., The FH2R can produce as much as 1,200 Nm 3 of hydrogen per hour (rated power operation) using renewable energy.

Let's personalize your content