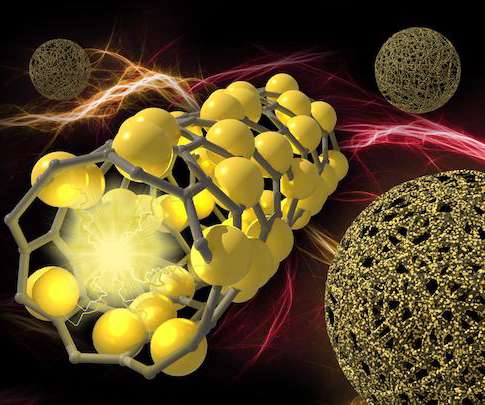

Ionic Mineral Technologies launches nano-silicon product for Li-ion cell manufacturers

Green Car Congress

MAY 17, 2023

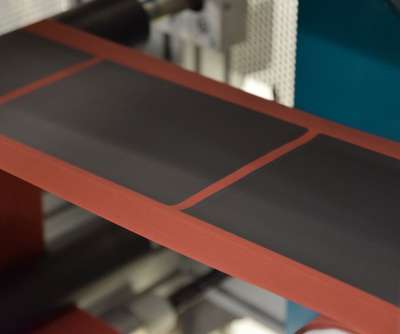

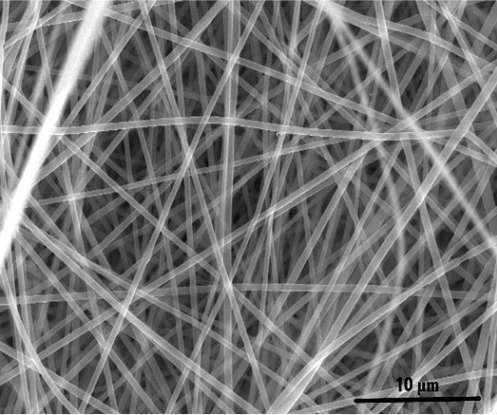

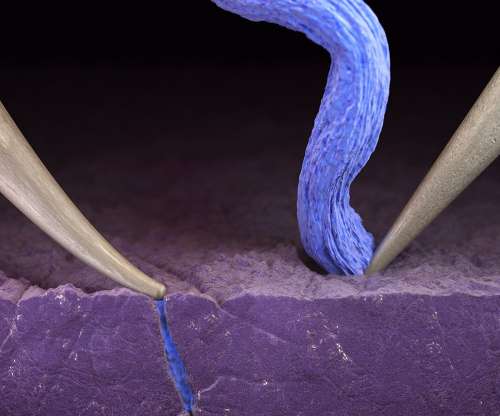

Ionic Mineral Technologies, a developer of advanced silicon anode battery materials, launched its Generation 1 Ionisil nano-silicon product for Li-ion cell manufacturers. Earlier post.) This silicon electrode was produced from an aqueous slurry highlighting the true ‘drop in’ nature of Ionisil, the company said.

Let's personalize your content