Volvo C40 Recharge LCA highlights huge potential of manufacturing and charging EVs with clean energy

Green Car Congress

NOVEMBER 3, 2021

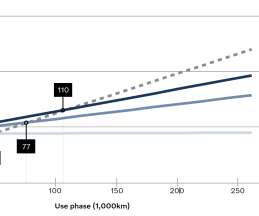

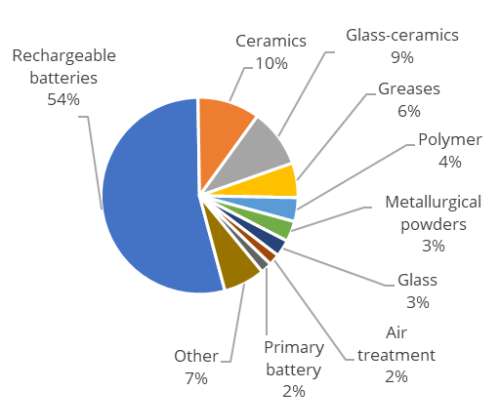

Volvo Cars has published a lifecycle analysis report on its second fully electric car, the C40 Recharge, which shows the potential CO 2 reductions if a car is built and charged using clean energy sources. Starting with the XC40 Recharge, its first electric car launched in 2019, Volvo Cars issues an LCA report for each fully electric model.

Let's personalize your content