Stanford researchers make ammonia from air and water microdroplets

Green Car Congress

MAY 1, 2023

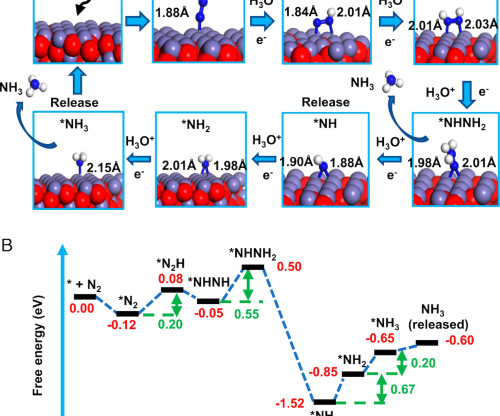

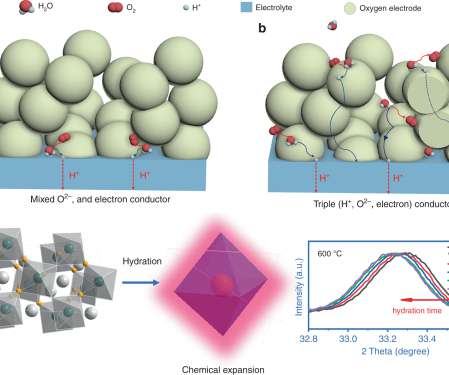

Stanford researchers, with a colleague from King Fahd University of Petroleum and Minerals, have developed a simple and environmentally sound way to make ammonia with tiny droplets of water and nitrogen from the air. Water microdroplets are the hydrogen source for N 2 in contact with Fe 3 O 4. The conversion rate reaches 32.9 ± 1.38

Let's personalize your content