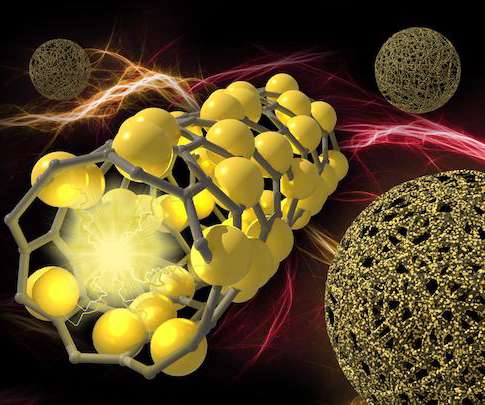

Ionic Mineral Technologies launches nano-silicon product for Li-ion cell manufacturers

Green Car Congress

MAY 17, 2023

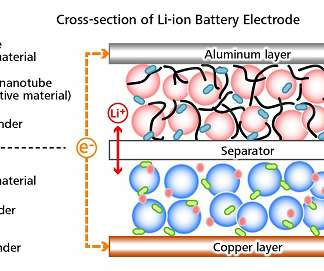

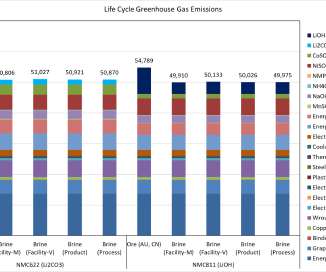

Ionic Mineral Technologies, a developer of advanced silicon anode battery materials, launched its Generation 1 Ionisil nano-silicon product for Li-ion cell manufacturers. The Ionic MT proprietary, continuous manufacturing process is among the lowest carbon footprint processes for producing battery materials, the company claims.

Let's personalize your content