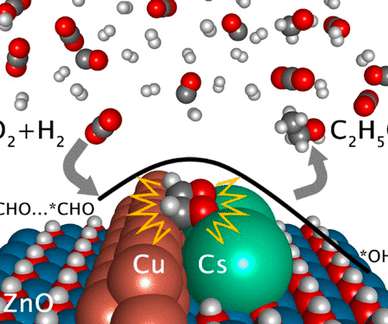

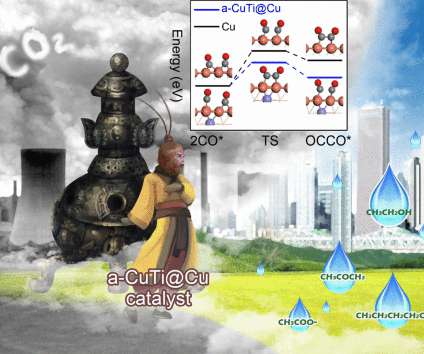

Three-part catalyst study advances conversion of CO2 to ethanol

Green Car Congress

SEPTEMBER 11, 2021

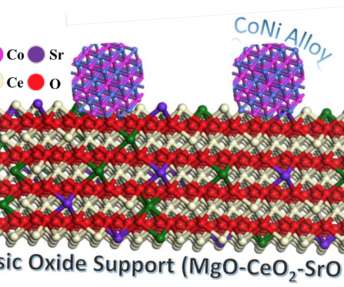

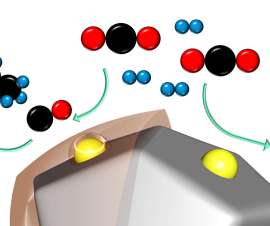

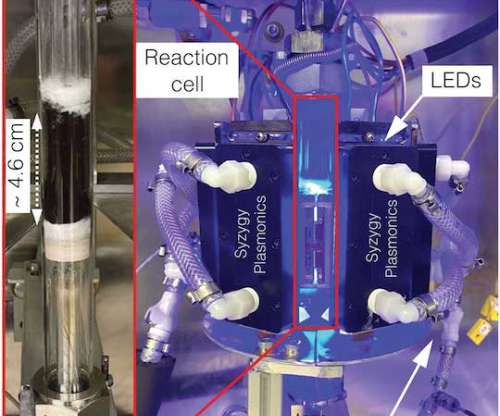

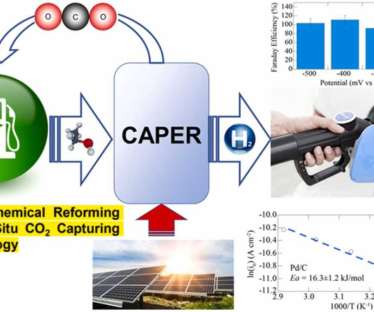

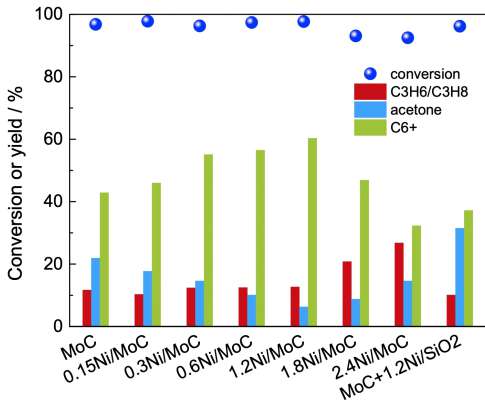

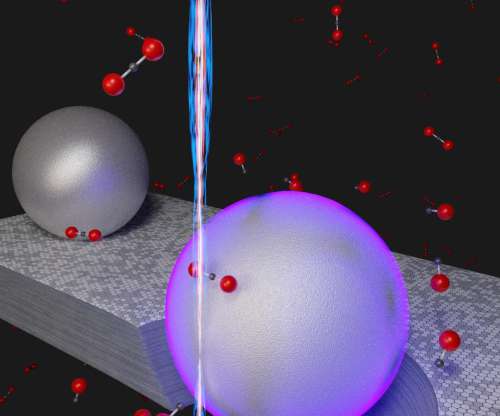

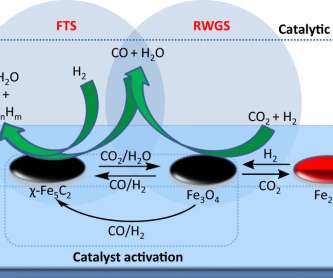

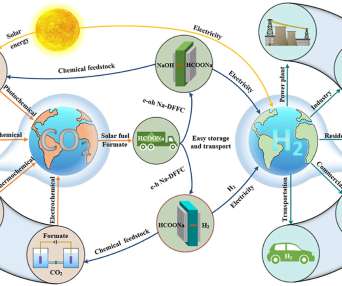

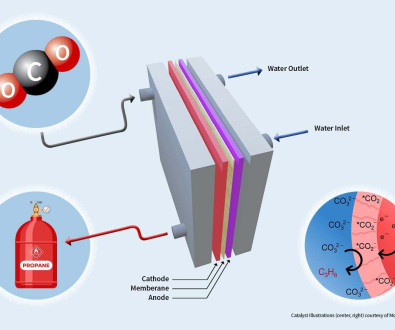

An international collaboration of scientists has taken a significant step toward the realization of a nearly “green” zero-net-carbon technology that can efficiently convert CO 2 and hydrogen into ethanol. There has been much work on carbon dioxide conversion to methanol, yet ethanol has many advantages over methanol.

Let's personalize your content