Virginia Tech team demonstrates green manufacturing method for Li-ion batteries

Green Car Congress

APRIL 25, 2020

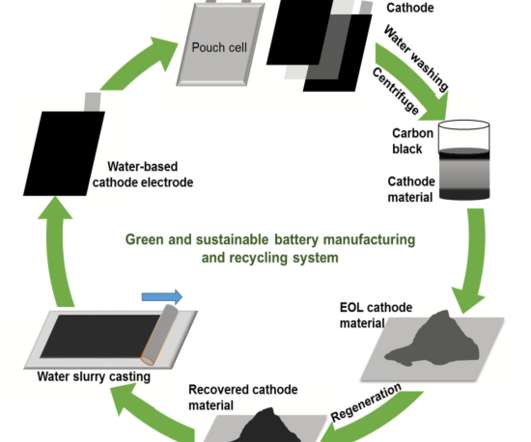

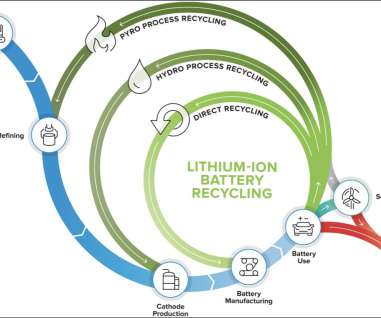

Researchers at Virginia Tech have demonstrated a green and more sustainable manufacturing method for LIBs in which no hazardous organic solvent is used during electrode manufacturing and recycling. Mass production of LIBs can result in environmental concerns during battery manufacturing and disposal. —Li et al.

Let's personalize your content