Rhodium Group estimates US GHG fell 2.1% in 2019, driven by coal decline

Green Car Congress

JANUARY 8, 2020

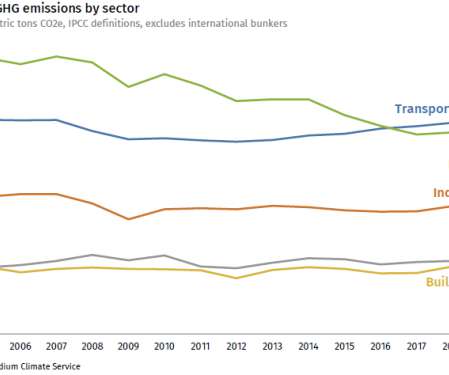

The Rhodium Group, an independent research provider, estimates that, after a sharp uptick in 2018, US greenhouse gas (GHG) emissions fell by 2.1% This decline was due almost entirely to a drop in coal consumption. Coal-fired power generation fell by a record 18% year-on-year to its lowest level since 1975. Coal-driven decline.

Let's personalize your content