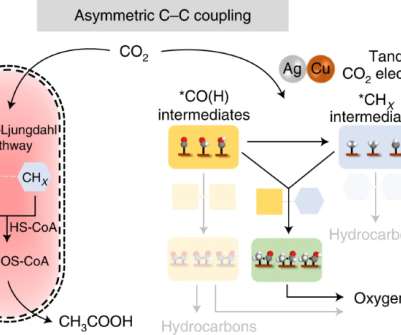

New system for more efficient CO2 electrolysis to hydrocarbon products

Green Car Congress

FEBRUARY 15, 2020

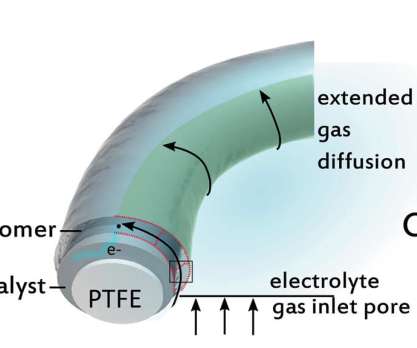

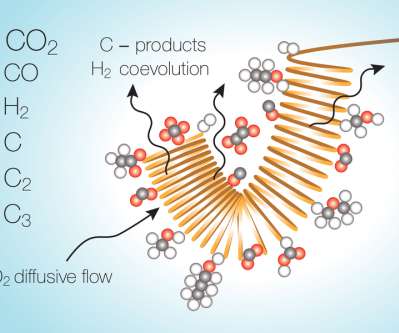

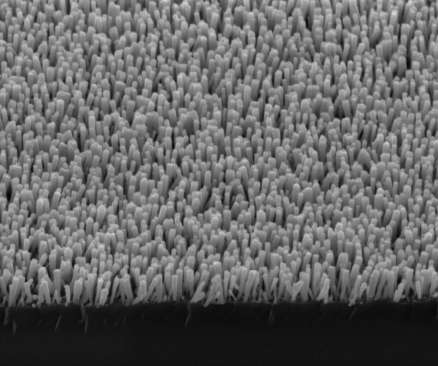

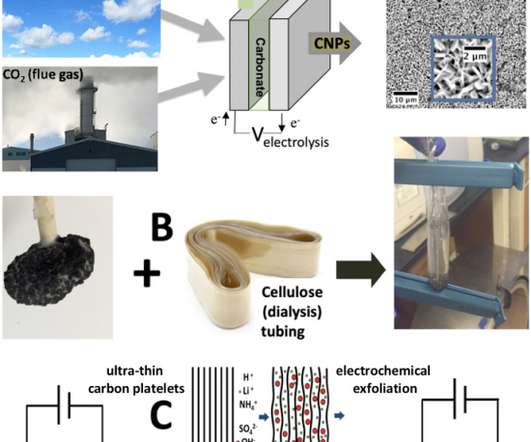

The researchers combined a copper electrocatalyst with an ionomer [polymers that conduct ions and water] assembly that intersperses sulfonate-lined paths for the H 2 O with fluorocarbon channels for the CO 2. Here, we present a catalyst:ionomer bulk heterojunction (CIBH) architecture that decouples gas, ion, and electron transport.

Let's personalize your content