1,000-Cycle Lithium-Sulfur Battery Could Quintuple Electric Vehicle Ranges

CleanTechnica EVs

JANUARY 14, 2022

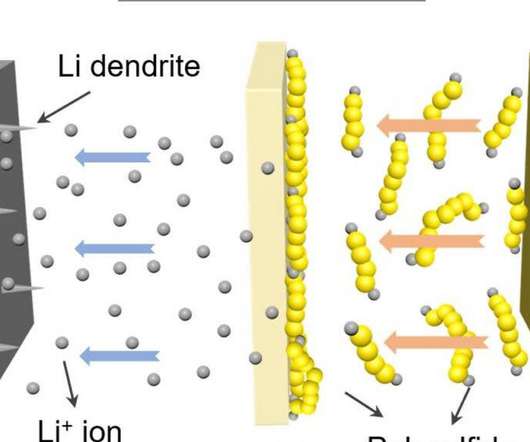

A new biologically inspired battery membrane has enabled a battery with five times the capacity of the industry-standard lithium ion design to run for the thousand-plus cycles needed to power an electric car.

Let's personalize your content