Lyten opens first automated battery pilot line in US to produce Li-sulfur batteries

Green Car Congress

JUNE 15, 2023

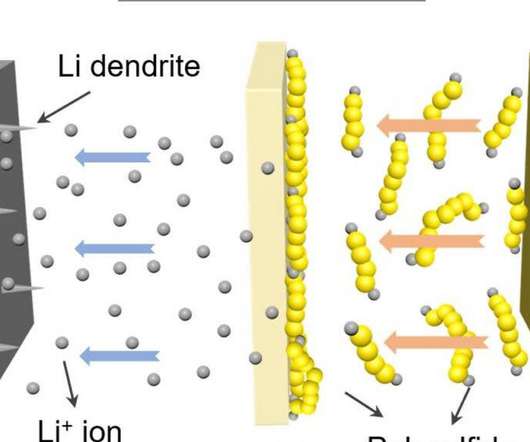

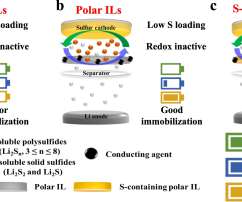

developer of the Lyten 3D Graphene decarbonization supermaterials platform, commissioned its Lithium-Sulfur battery pilot line at its facility in Silicon Valley. Battery delivery will be used to support testing, qualification and initial commercialization across the sectors. Lyten, Inc., Earlier post.)

Let's personalize your content