Fluorine-incorporated interface enhances cycling stability of Li metal batteries with Ni-rich NCM cathodes

Green Car Congress

MARCH 1, 2020

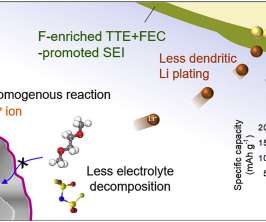

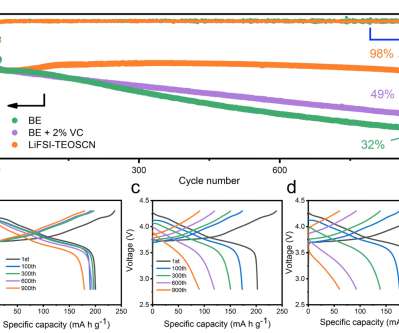

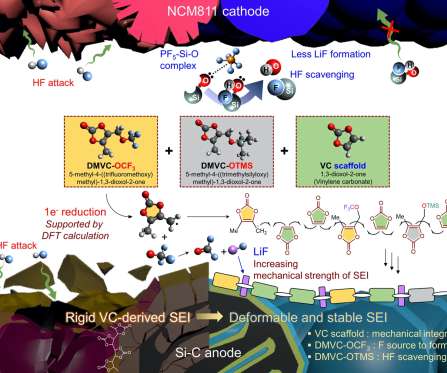

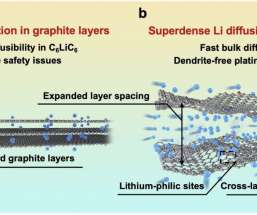

A joint research team led by Professor Nam-Soon Choi and Professor Sang Kyu Kwak in the School of Energy and Chemical Engineering at Ulsan National Institute of Science and Technology (UNIST) has developed an ion concentrate electrolyte using a solvent containing fluorine atoms. Li/Li + ). —Lee et al.

Let's personalize your content