Sumitomo considering marketing new lower-temperature molten-salt electrolyte battery to automakers for EVs and hybrids

Green Car Congress

NOVEMBER 11, 2011

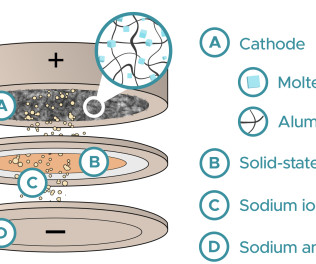

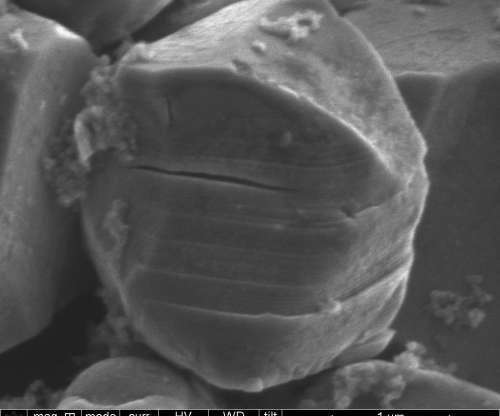

Construction of the molten-salt electrolyte battery. is considering targeting its lower-temperature molten-salt electrolyte battery, being developed in partnership with Kyoto University ( earlier post ), to makers of electric and hybrid passenger cars, according to Bloomberg. Source: Sumitomo. Click to enlarge.

Let's personalize your content