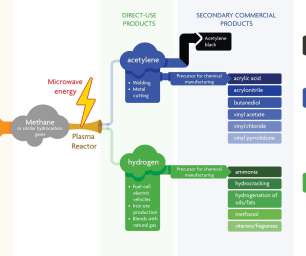

Transform Materials plasma process converts abundant natural gas into high-value hydrogen and acetylene

Green Car Congress

SEPTEMBER 30, 2020

Transform Materials has developed a novel and sustainable microwave plasma reactor process to convert natural gas into high-value hydrogen and acetylene, thereby opening up a new pathway for green chemical manufacturing. Oxidation of methane also introduces impurities in the product stream.

Let's personalize your content