TUAT team develops more efficient method to recover heavy oil using novel chemical flooding

Green Car Congress

NOVEMBER 24, 2020

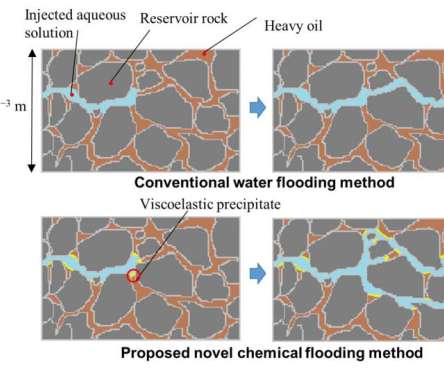

By making use of a previously undesired side effect in oil recovery, researchers at Tokyo University of Agriculture and Technology (TUAT) have developed a method that yields up to 20% more heavy oil than traditional methods. Generally, less than 10% of heavy oil may be produced from reservoirs by natural flow after drilling the well.

Let's personalize your content