Li-Cycle starts operations at its first European lithium-ion battery recycling facility

Green Car Congress

AUGUST 2, 2023

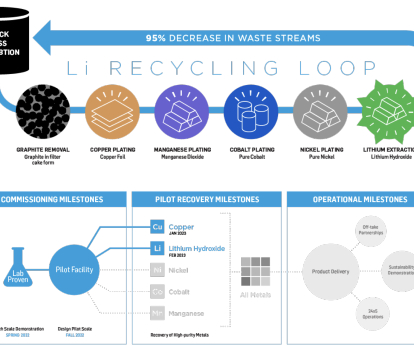

Li-Cycle Holdings announced the start of commercial operations at its first Spoke recycling facility in Europe, located in Magdeburg, Germany. Each main line has the capacity to process up to 10,000 tonnes of lithium-ion battery material per year.

Let's personalize your content