IIT, Argonne team designs Li2O-based Li-air battery with solid electrolyte; four-electron reaction for higher energy density

Green Car Congress

FEBRUARY 25, 2023

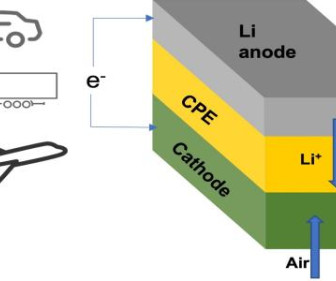

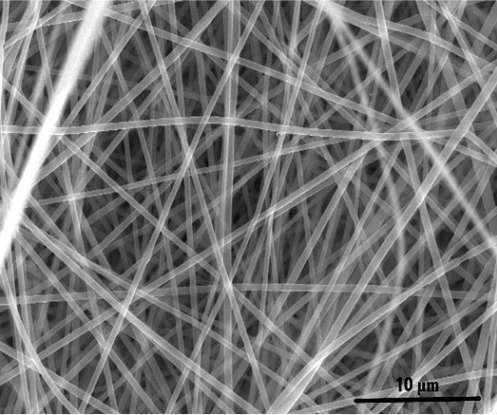

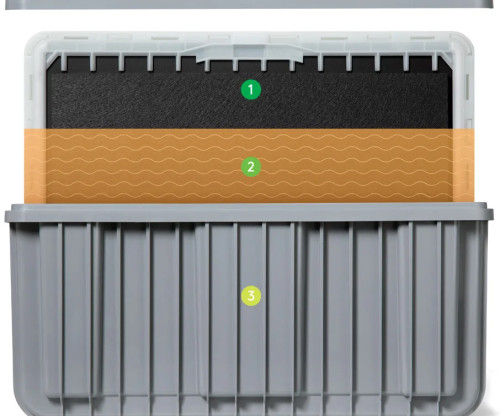

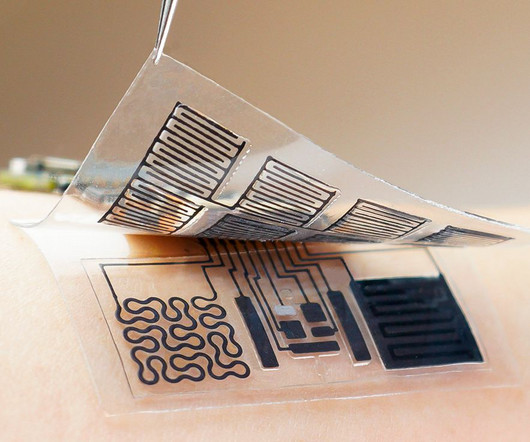

Researchers at the Illinois Institute of Technology (IIT) and US Department of Energy’s (DOE) Argonne National Laboratory have developed a lithium-air battery with a solid electrolyte. The battery is rechargeable for 1000 cycles with a low polarization gap and can operate at high rates. Image by Argonne National Laboratory.)

Let's personalize your content