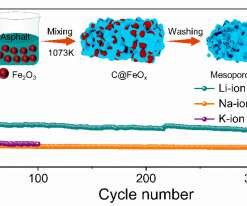

Researchers convert spent asphalt to mesoporous carbon anode material for Li/Na/K-ion batteries

Green Car Congress

OCTOBER 7, 2021

Researchers at Changsha University of Science & Technology in China have used spent asphalt to produce a high-performance universal Li/Na/K-ion anode material. As an anode material for Li-ion batteries, the mesoporous carbon exhibits a reversible capability of 674.2 —Xie et al. 2021.230593. 2021.230593.

Let's personalize your content