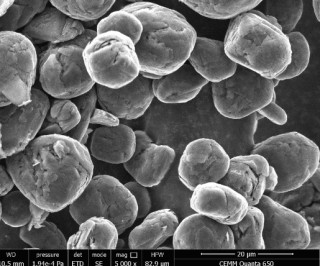

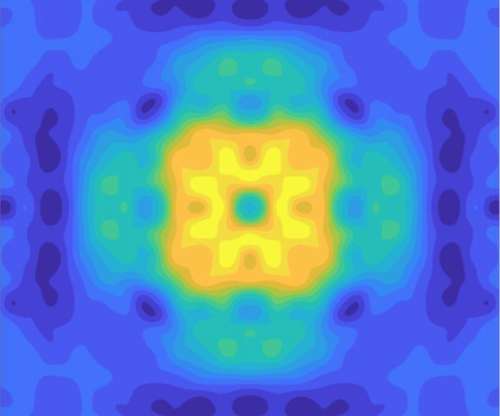

MGX Minerals partners with University of British Columbia to develop metallurgical silicon-based anodes for high-energy Li-ion batteries

Green Car Congress

DECEMBER 21, 2018

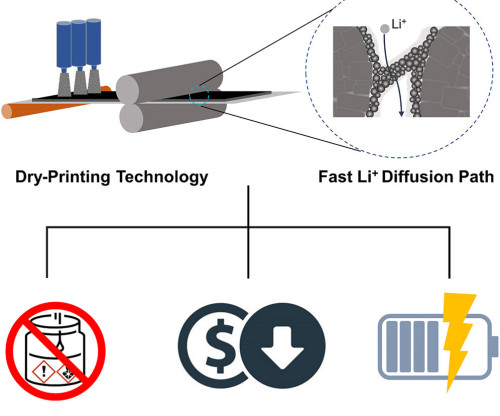

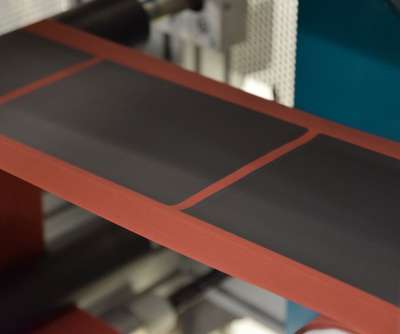

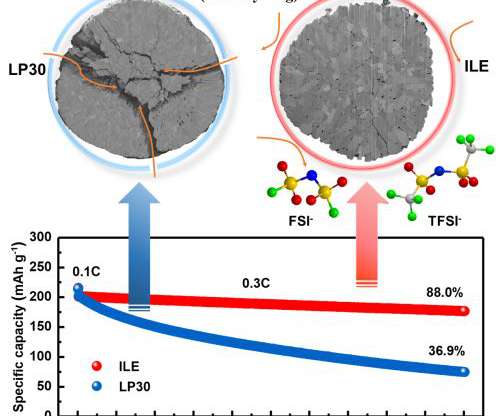

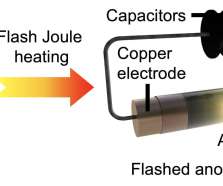

is funding a research consortium with the University of British Columbia (UBC) to develop a low-cost and scalable method for fabricating silicon-based anodes to improve the energy density of Li-ion batteries. Fabrication and evaluation of Si-based anode for Li-ion batteries. Canada-based MGX Minerals Inc.

Let's personalize your content