RPI team develops method to use paper-making by-product in lithium-sulfur batteries

Green Car Congress

APRIL 3, 2018

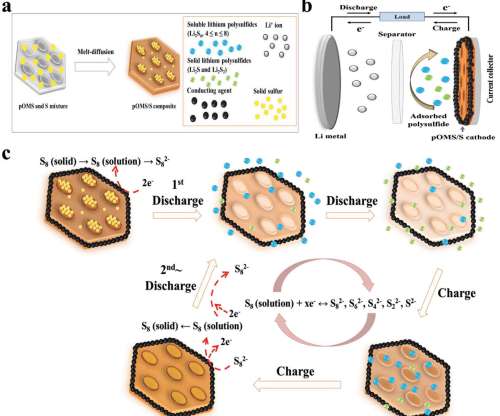

Researchers at Rensselaer Polytechnic Institute (RPI) have now developed a method to use this cheap and abundant waste byproduct to build a components for lithium-sulfur batteries. The micropores provide sufficient space to capture substantial amounts of sulfur and accommodate the large volume change of sulfur during cycling.

Let's personalize your content