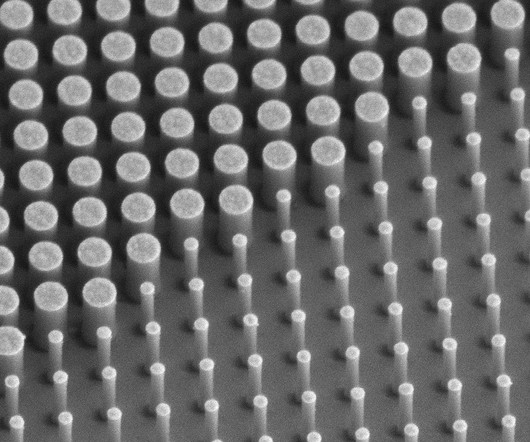

Ford using autonomous mobile robot to operate 3D printers at Advanced Manufacturing Center

Green Car Congress

MARCH 17, 2022

For example, the Carbon 3D printer tells the KUKA autonomous mobile robot when the printed product will be finished, then the robot lets the printer know the robot has arrived and is ready for pick-up. Not only does this increase throughput, it reduces the cost of custom-printed products.

Let's personalize your content