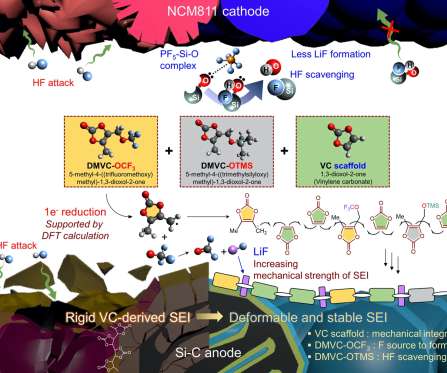

Fluorine-incorporated interface enhances cycling stability of Li metal batteries with Ni-rich NCM cathodes

Green Car Congress

MARCH 1, 2020

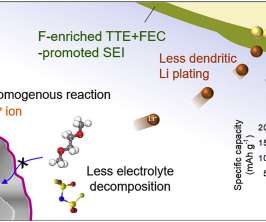

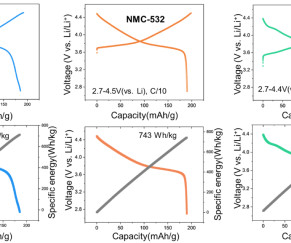

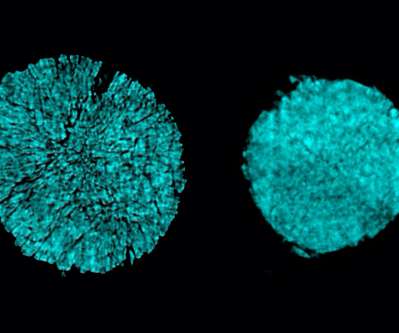

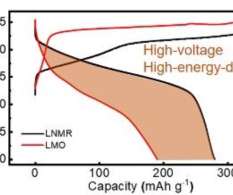

The electrolyte evenly formed a protective film on the negative electrode and the positive electrode of the lithium metal battery, increasing the lifespan and output of the entire battery. Li/Li + ). O 2 full cell, with a high Coulombic efficiency of 99.98% after 100 cycles at 25 °C. —Lee et al. —Professor Kwak.

Let's personalize your content