Ionic Mineral Technologies launches nano-silicon product for Li-ion cell manufacturers

Green Car Congress

MAY 17, 2023

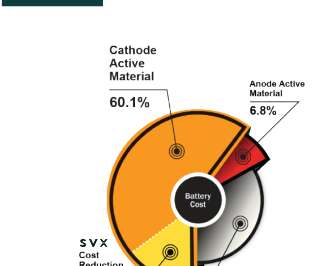

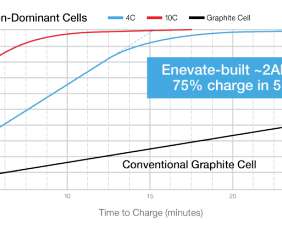

Ionic Mineral Technologies, a developer of advanced silicon anode battery materials, launched its Generation 1 Ionisil nano-silicon product for Li-ion cell manufacturers. Earlier post.) This technology can increase the capacity at the anode level by >100% compared to graphite batteries. Based on Ionisil having 7.5x

Let's personalize your content