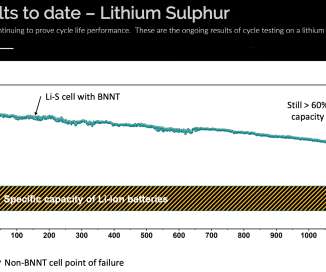

U Mich team develops 1,000-cycle lithium-sulfur battery

Green Car Congress

JANUARY 12, 2022

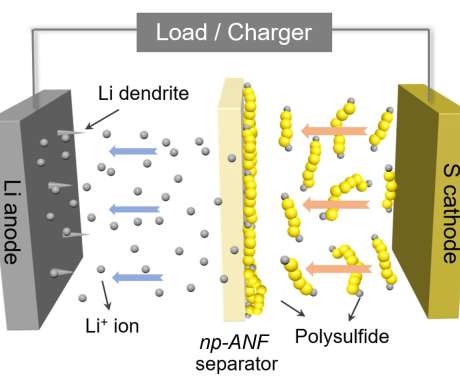

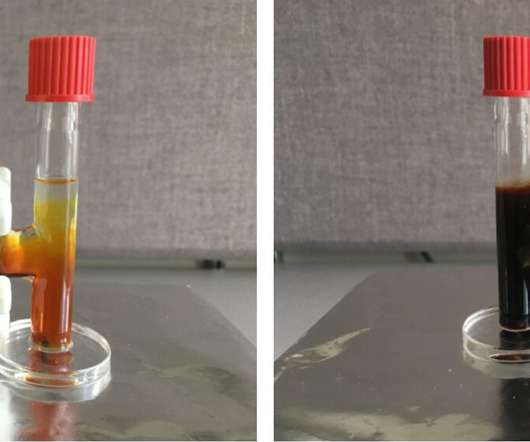

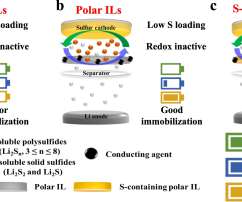

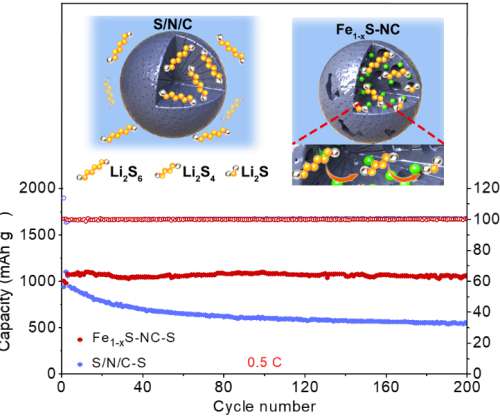

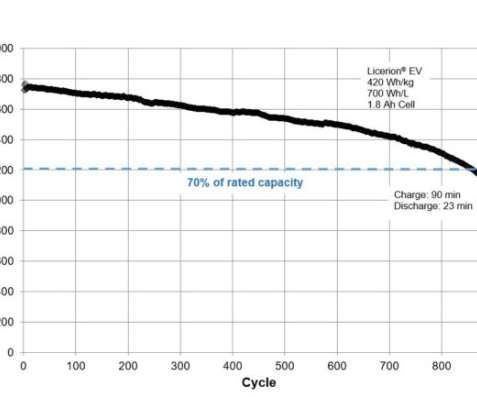

A University of Michigan team has shown that a network of aramid nanofibers, recycled from Kevlar, can enable lithium-sulfur batteries to overcome their Achilles heel of cycle life, delivering an estimated 1,000 real-world cycles. Positively charged lithium ions, however, could pass freely.

Let's personalize your content